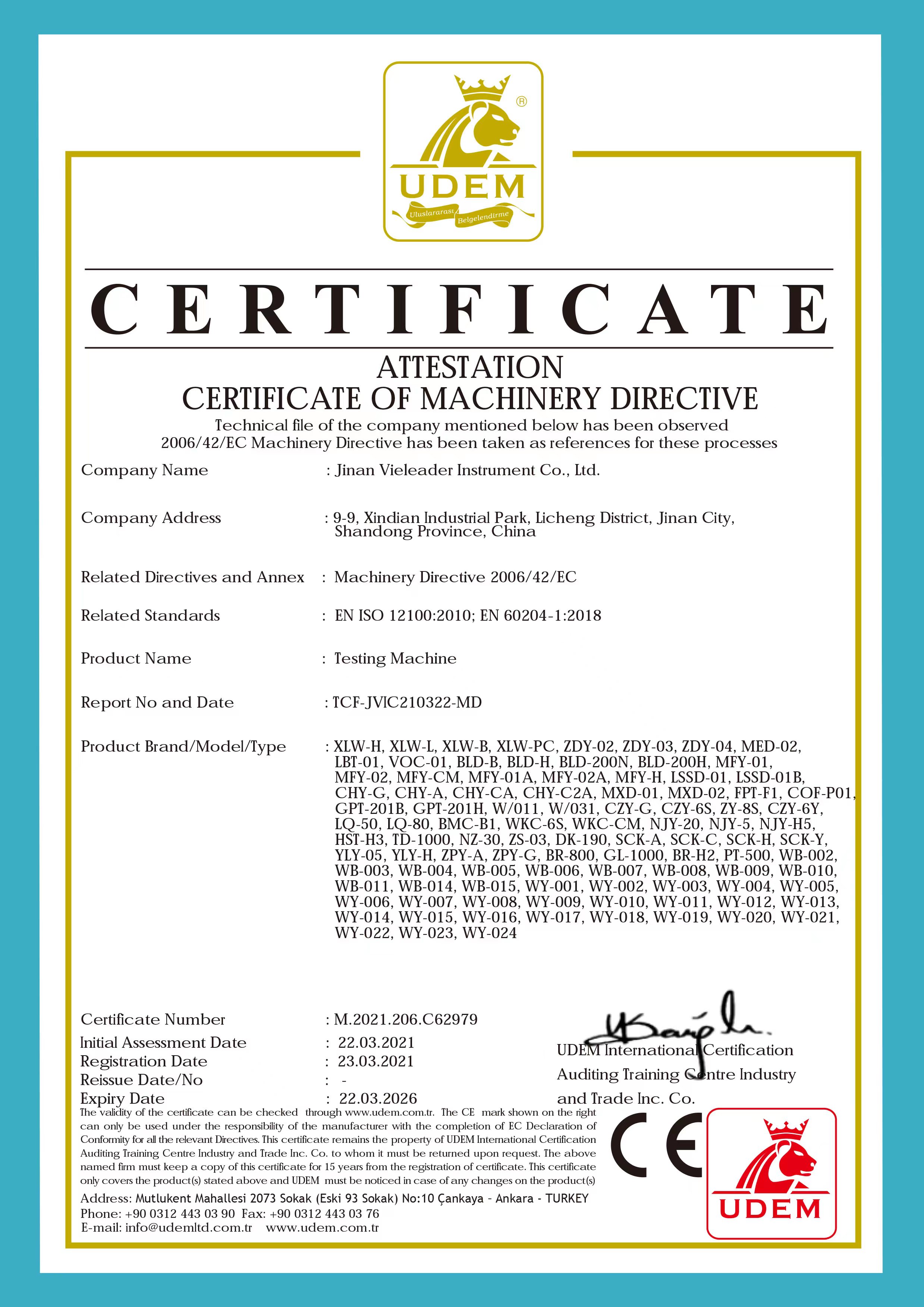

Bottle Cap Torque Tester

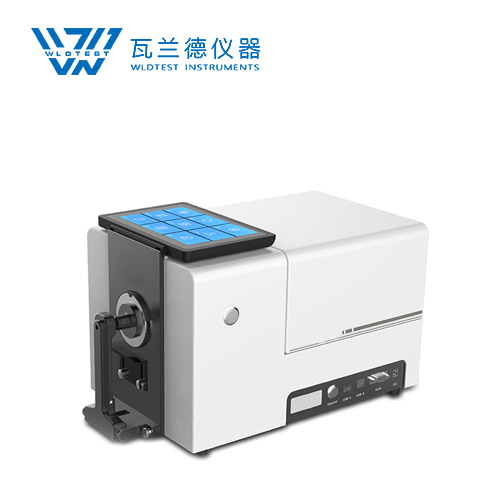

The Automatic Torque Tester NJY-H5 is the automatic torque tester with manipulator, which is one professional testing instrument that can be used to measure the application torque and removal torque of the caps of bottles, spout bags and flexible tube packages. The NJY-H5, featuring great stability and high precision, is an indispensable testing instrument in manufacturing process. The application torque and removal torque of caps or closures of bottles, spout bags and flexible tube packages are important online and offline production parameters for the manufacturers, they may influence the transportation and consumption of the products.

The Automatic Torque Tester NJY-H5 is equipped with 7 inch touch screen, micro printer, one-button operation, user-friendly interface, fully automatic testing process.

Two test modes are available on the Automatic Torque Tester and both application torque and removal torque could be tested. Three level authority management of GMP and multiple international units are expressed on the professional software for customers reference and comparison.

- WLDTest

- China

- 10 working days

- 100sets/month

- Information

- Video

- Download

NJY-H5 Automatic Torque Tester

The Digital Torque Tester NJY-H5 is the automatic torque tester with manipulator, which is one professional testing instrument that can be used to measure the application torque and removal torque of the caps of bottles, spout bags and flexible tube packages. The NJY-H5, featuring great stability and high precision, is an indispensable testing instrument in manufacturing process. The application torque and removal torque of caps or closures of bottles, spout bags and flexible tube packages are important online and offline production parameters for the manufacturers, they may influence the transportation and consumption of the products.

Professional technology

7 inch touch screen, one-button operation, user-friendly interface

The instrument conforms to the requirements of GMP, real time dynamic display of the testing process.

Dual test modes including application torque test and removal torque test

The tester supports automatic gripping, opening and fastening, which minimizes the error caused by manual operations and improves the testing accuracy and repeatability

Gripping force, fastening force and turning speed of the cap can be adjusted freely

Intelligent designs of overload protection, automatic zeroing and error alert for safe test operation

Chinese and English languages can be selected

Automatic data storage and power failure memory functions Historical data can be reviewed and printed easily no up limits for test data storage on the professional software.

Test data is expressed in multiple international units for reference and comparison

Micro-printer and USB data ports for data exporting and data transfer

Test Standard

ASTM D2063, ASTM D3198, ASTM D3474, BB/T 0025, BB/T 0034, GB/T 17876

Application

Bottle Packages:Application and removal torque test of the bottle caps for bottled packages for food, pharmaceuticals, e.g. beverage or tablet bottles

Flexible Tube Packages: Application and removal torque test of flexible tube packages for food, pharmaceuticals and cosmetics, e.g. eye-drop, hand cream and shoe polish

Technical Specification

Index | Parameter |

Load Cell Capacity | 5 Nm(standard) |

20 Nm(optional) | |

40 Nm (optional) | |

Accuracy | 0.5 |

Resolution | 0.0001 Nm |

Twisting speed | 10r/min(adjustable) |

Clamp force | Adjustable according to the sample |

Clamp Range | Φ5 mm~Φ170 mm (diameter) |

Bottle Height | Up to 400mm |

Clamp Mode | Pneumatic |

Data Numbers | 1~999 |

(No up limits on professional software,and multiple units available.) | |

Gas Supply | Compressed Air (Out of supply scope) |

Gas Supply Pressure | 0.7Mpa (101.5psi) |

Power Supply | 220V 50Hz |

Dimension | |

Net Weight |

Configuration

Standard | Instrument、Micro Printer |

Optional | Professional Software and communication cable |