Electronic Tensile Testing Machine

XLW-H is an intelligent electronic tensile testing machine specializing in testing the mechanical properties of various soft packaging materials, such as tensile properties; mainly used for testing the thermal bonding strength, tensile strength, peeling strength, breaking elongation of pharmaceutical packaging materials, aluminum foil, PVC hard sheet, composite film, syringe, card bottle and other products; ampoule bottle breaking force testing; Testing of opening force, puncture force and tearing force of aluminium sheet for aluminium-plastic composite cover: testing functions of syringe sealing, sliding performance, connecting force between needle and needle seat, etc..

XLW-H intelligent electronic tensile testing machine is a multi-functional testing instrument combined with different fixtures. The intelligent electronic tensile testing machine ultra-high accuracy (0.5 level) ensures the accuracy of the test; seven independent test procedures, various specifications of force sensors, stepless speed change, can meet the various test conditions of users; intelligent operation software not only facilitates users to control equipment, but also provides a variety of practical functions such as data analysis and comparison.

- WLDTEST

- China

- 10 working days

- 100 sets/month

- Information

- Video

- Download

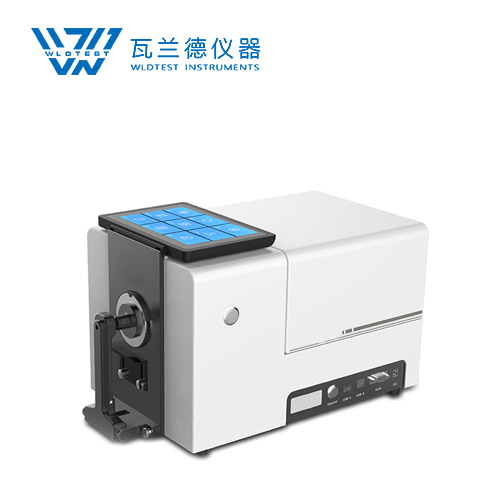

XLW-H Intelligent Electronic Tensile Testing Machine

XLW-H is an intelligent electronic tensile testing machine specializing in testing the mechanical properties of various soft packaging materials, such as tensile properties; mainly used for testing the thermal bonding strength, tensile strength, peeling strength, breaking elongation of pharmaceutical packaging materials, aluminum foil, PVC hard sheet, composite film, syringe, card bottle and other products; ampoule bottle breaking force testing; Testing of opening force, puncture force and tearing force of aluminium sheet for aluminium-plastic composite cover: testing functions of syringe sealing, sliding performance, connecting force between needle and needle seat, etc., is a multi-functional testing instrument combined with different fixtures. Its ultra-high accuracy (0.5 level) ensures the accuracy of the test; seven independent test procedures, various specifications of force sensors, stepless speed change, can meet the various test conditions of users; intelligent operation software not only facilitates users to control equipment, but also provides a variety of practical functions such as data analysis and comparison.

Professional technology

10 Inch Touch screen, fashionable and convenient man-machine interface

Selection of a variety of pilot projects to meet the needs of the vast majority of industry applications

The force measuring system has high precision, good linearity and fast response.

Sensor Overrange Protection

The motion drive system is stable and has high running accuracy.

Intelligent configurations such as limit protection, overload protection, automatic return, and power-off memory of motion mechanism ensure the safety of users and instruments themselves.

Start-up automatic zero calibration, support manual sensor zero clearing

Real-time display of test curves shows the changing trend of force value in the process of test.

Products conform to GMP user three-level authority.

Test data history can be queried, data can not be changed, auditable traceability

Statistical analysis of single and group test results

Micro printer, note printing test statistics at any time

Standard USB communication interface

Specialized computer communication software can display real-time test data, analyze and process data, and save data.

Optional pneumatic clamping, reduce operation time, more smooth operation experience

Extensible network transmission interface, test data uploaded directly to cloud server, global remote query.

Application

XLW-H Intelligent Electronic Tensile Testing Machine has abundant applications, with more than 100 different sample fixtures for users to choose, and can meet the test requirements of more than 1000 kinds of materials. It also provides customized services to meet the test needs of different users according to the different materials of users.

Some examples of application:

Basic application |

Extended application (Need special accessories or restructuring) | |||

Tensile Property | Simulated skin puncture resistance | Film puncture force | Puncture force of bag cover for infusion | Puncture/Draw Force of Soft Rubber Bottle Plug |

Tensile Strength and Deformation Rate | Opening force of combined cover | ZD style Cap tearing force | Tearing force of oral liquid lid | Puncture/pull-out force of oral liquid cover |

Breaking force | Drawing Force of 90 Degree Inclined Infusion Bag Cover | Drawing force of the cover of infusion bag with bag | Drawing Force of 23 Degree Tilt Bottle Cap | Puncture/Drawing Force with Bottle Cap and Rubber Plug |

Tear resistance | 90 Degree Peeling Force of Adhesive Tape | Binding Page Tearing Force | 90 Degree Waterborne Plaster Peeling Force | Stickies tearing force |

Heat Sealing Strength Performance | Adhesion Strength Test (Soft) | Adhesion Strength Test (Hard) | Peeling force of hose cover | Catheter and catheter joint detachment force |

90 degree peeling | Cosmetic brush pull-out force | Brush pull-out force | Rope breaking force | Opening power of jelly cup and yogurt cup |

180 degree peeling | Peeling force of cup membrane of milk cup | Plug pull-out force | 45 Degree Peeling Force of Bottle Film | Self-sealing bag opening pull |

Core peeling force of magnetic card | 90 Degree Peeling Force of Magnetic Card | Tearing force of heat sealing film | Protective Membrane Separation Force | |

Separation force of release paper | Tearing force of trousers | Unwinding force of tape | Pressure Resistance of Plastic Bottles | |

20 Degree Slope Peeling Force | 135 degree bolt peeling force | Floating Roll Peeling Fixture | Eccentric fixture | |

Wide sample fixture | Japanese fixture | British style fixture | ||

Testing principle

The sample is clamped between the two clamps of the fixture. The relative motion of the two clamps is made. The force and displacement changes during the test are collected through the force sensor on the moving clamp and the displacement sensor built in the machine. The tensile, tearing and deformation rate of the sample are calculated.

The instrument meets many national and international standards:GB 13022、GB 8808、GB 1040、GB 4850、GB 7753、GB 7754、GB 453、GB/T 17200、GB/T 16578、GB/T 7122、GB/T 2790、GB/T 2791、GB/T 2792、ASTM E4、ASTM D828、ASTM D882、ASTM D1938、ASTM D3330、ASTM F88、ASTM F904、ISO 37、JIS P8113、QB/T 2358、QB/T 1130 、YBB00152002-2015、YBB00212005-2015 、YBB00232005-2015、YBB00222005-2015、YBB00182004-2015、YBB00202005-2015、YBB00242002-2015、YBB00212004-2015、YBB00132005-2015、YBB00142005-2015、YBB00152005-2015

Technical index

Model Item | XLW-H Intelligent Electronic Tensile Testing Machine |

Range | 30N、100N,500N,1000N |

Accuracy of force measurement | 0.5 class |

Force Resolution | 0.001N |

Displacement accuracy | 0.5 class |

Displacement resolution | 0.1mm |

Test speed | Stepless speed regulation,5-800 mm/min |

Travel | 800mm |

Power | 220 V/50Hz/60W |

Size | 520mm*380mm*1400mm |

Net Weight | 72 kg |

Environmental requirements | temperature 10 ℃ ~ 40 ℃. humidity 20%~80% |

Product configuration

Standard configuration | Host computer, micro printer, pneumatic fixture, professional software, communication cable |

Optional configuration | Breaking force fixture, opening force fixture for modular cover, stretching fixture, pinpoint puncture force test fixture, sliding test fixture, body tightness test fixture, thermal strength test fixture, connecting force fixture, pulling force fixture, full opening force fixture |