- Home

- >

- Products

- >

- Leak Tester

- >

Leak Tester

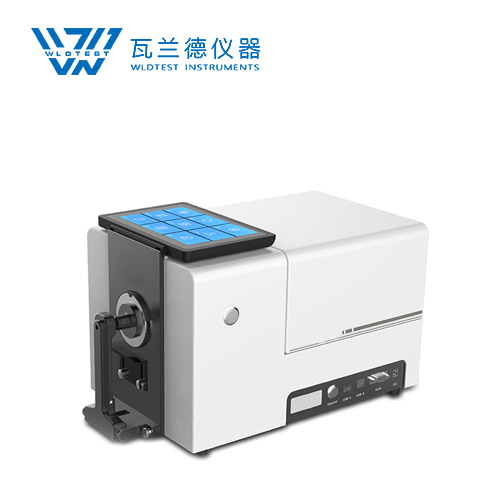

MFY-CM the leak tester is professionally designed for the leakage tests of packages for food, drugs, medical instruments, household chemical products, cars, electronic components, stationeries and other industrial products. The instrument also can be used to test seal performance of specimens after falling and compression tests.

The Leak Tester conforms to the standards ASTM D3078 The determinaion of leaks in flexible packaging by bubble emission method.

The test principle of Leak Tester MFY-CM:Firstly submerge the specimen in the water in the vacuum chamber, and then evacuate the vacuum chamber to form differential pressure between the inside and outside of specimen. The seal property can be obtained by observing the steady progression of bubbles from the specimen or observing how the specimen expands and restores to its original shape after vacuum release.

- WLDTEST

- China

- 10working days

- 100sets/month

- Information

- Video

- Download

MFY-CM Leak Tester

MFY-CM the Leak Tester is professionally designed for the leakage tests of packages for food, drugs, medical instruments, household chemical products, cars, electronic components, stationeries and other industrial products. The Instrument also can be used to test the seal performance of specimes after falling and compression tests.

Professional Technology

7-inch color touch screen, user-friendly operation more convenient;

Two test modes, pressure maintaining and pressure increasing, meet the test requirements of different materials;

Full automatic control, pressure vacuumization, pressure maintaining, pressure compensation, timing, back blowing, printing, saving and data uploading are completed automatic;

Equipped with micro printer, USB data interface, support PC software measurement and controlling, the test unit could exchange between mbar and kPa;

Historical test records could be saved automatically.The test data could be export to Excel format;

Three level authority management meets the GMP requirment, test record could be audit and tracked;

The test results are synchronously uploaded to the cloud server for storage, and can be browsed around the world if there is a network;

Dual backup of local data and cloud data to ensure the data safely;

Bilingual choice of Chinese and English, convenient for customer language switching;

Application

Glass bottle、cans、boxes、pipes, plastic bottle、cans、boxes、pipes, metal bottle、cans、boxes、pipes, plastic bags and pouches, paper plastic composite bags and pouches, pen refills etc.

Test Principle

Firstly submerge the specimen in the water in the vacuum chamber, and then evacuate the vacuum chamber to form differential pressure between the inside and outside of specimen. The seal property can be obtained by observing the steady progression of bubbles from the specimen or observing how the specimen expands and restores to its original shape after vacuum release.

Test Standard

GB/T 15171、ASTM D3078、GB/T 27728、YBB00112002-2015、YBB00122002-2015、YBB00262002-2015、YBB0005-2015、YBB00092002-2015、YBB00392003-2015、YBB00112002-2015.

Technical Index

Model Item | MFY-CM leak tester |

Screen | 7 Inch Touch Screen |

Vacuum degree | 0~-90kpa |

Accuracy | 1 Grade |

Pressure resolution | 0.1kpa |

Negative pressure generation mode | Vacuum generator |

Vacuum chamber size | Φ270mm×210 mm (H) (Standard) Φ360mm×585 mm (H) (optional) Φ460mm×330 mm (H) (optional) |

Gas pressure | 0.7MPa (supplied by the user) |

Air connection | Φ6mm polyurethane pipe |

Power supply | 220 V/50Hz |

Size | 370mm(L)×300mm(B)×450mm(H) |

Net weight | 12 kg |

Configuration

Standard configuration | Instrument, micro printer, vacuum chamber |

Optional purchase | Vacuum chamber, Professional software |

Note | The air source interface of the machine is Φ 6mm polyurethane pipe, which is provided by the user. |