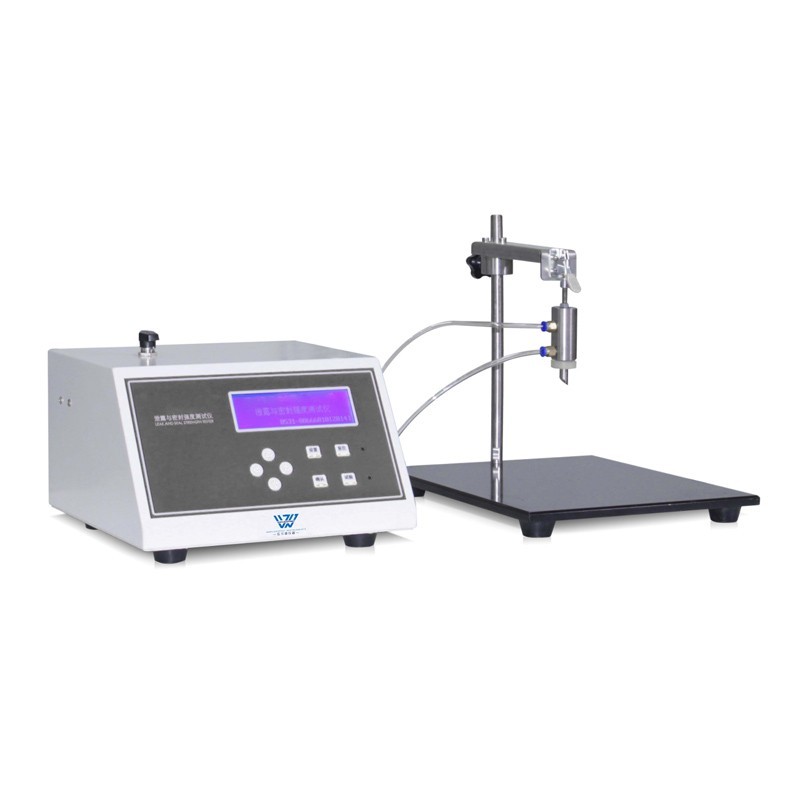

Leakage And Sealing Strength Tester

LSSD-01 Leak and Seal Strength Detector is professionally applicable to the quantitative determination of seal performance, seal quality, burst pressure, compression resistance, torsion force and joint/disengaging force of flexible packages, aseptic packages, various plastic pilfer-proof closures, flexible tubes, caps and other materials.

The leak and seal strength detector complies to multiple international standards including GB、ASTM、ISO. The tester applied positive pressure method. With the wide test range and the application field is broad.

Three test modes available of burst, creep, creep to failure and pressure retaining to meet different test requirements. Dual test methods of restraint distension and unrestraint distension at customer's choice. The sample supporter height is adjustable according to the sample size.

The leak and seal strength detector could save test data automatically and power failure memory to prevent data loss. The embedded micro-printer and USB ports for data transmission available.

- WLDTest

- China

- 10 working days

- 100sets/month

- Information

- Video

- Download

LSSD-01 Leakage and seal strength tester

LSSD-01 The leakage and sealing strength tester is suitable for the quantitative measurement of sealing strength, heat sealing quality, bursting pressure of the whole bag and sealing leakage performance of soft package and aseptic package formed by various heat sealing and bonding processes, as well as the quantitative measurement of sealing performance of various plastic pilfer-proof bottle caps, as well as the overall sealing performance, pressure resistance strength, cap body connection strength and shedding strength of various flexible pipes The quantitative determination of heat sealing strength and binding strength.

Professional technology

GB、ASTM、ISO Multiple standards compatibility.

Positive pressure design principle, simple operation, stable and reliable performance.

The test range is optional, the test range is wide and the application field is wide.

Double test method of expansion inhibition and expansion non inhibition.

A variety of test modes for fracture test, creep test and creep to fracture test.

The "one key" operation in the test process is intelligent and efficient.

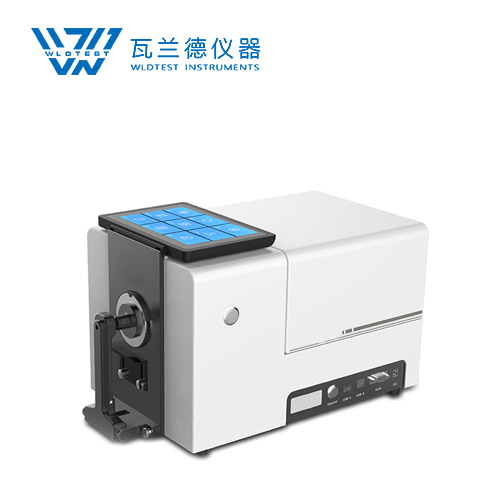

Test data high-definition large screen liquid crystal display, results automatic statistics, printing.

Test accessories support, flexible test mode, compatibility and diversification.

Standard USB interface configuration, computer software support, results of multiple units display.

The test data can be shared between LAN and Internet.

Rich application

Basic application | Plastic composite bag | It is suitable for pressure rupture test of various plastic film, aluminum film, paper plastic composite, aluminum plastic composite and other packaging bags |

Flexible pipe test | All kinds of washing and chemical products packaging hose and other fields of goods packaging hose. The hose can include toothpaste tube, facial cleanser, cosmetics, various medicinal ointment tubes, food packaging hose and so on | |

Creep test | It is suitable for creep test of various packing bags and boxes | |

Creep to rupture | It is suitable for testing creep to rupture of various packing bags and boxes | |

Extended application | Blister package rupture test | It is suitable for pressure test of all kinds of blister packaging |

Aerosol valve test | It is suitable for testing the sealing performance of various aerosol valves. Aerosol valves include a variety of pesticides, mousse, gel water, pharmaceutical spray, self spray, etc | |

Three side heat sealing material | It is suitable for the pressure test of packaging bag with only three sides sealed and one side open | |

High pressure test | The maximum test pressure can reach 1.6 MPa | |

Anti theft bottle cap | It is suitable for sealing performance test of various anti-theft bottle caps. The anti-theft bottle cap can include coke bottle cap, mineral water purified water bottle cap, beverage bottle cap, vegetable oil barrel cap, non-staple food seasoning bottle cap (soy sauce, vinegar, cooking wine, etc.), easy to open three piece cans (beer, beverage cans, etc.), paper packaging cans (cylindrical, various chips, shrimp chips), etc |

Testing principle

LSSD-01 The leak sealing instrument adopts the principle of positive pressure method: after the gas with certain pressure is filled into the sample by setting parameters, the pressure sensor detects the change of air pressure inside the sample to judge the overall sealing performance of the sample, and tests the pressure resistance and bursting performance of the sample with the specified air pressure.

Test Standard

The instrument meets many national and international standards:GB 10440、GB 18454、GB 19741、GB 17447、ASTM F1140、ASTM F2054、ISO 11607-1、ISO 11607-2、GB/T 17876、GB/T 10004、GB/T 10005、 BB/T 0003、BB/T 0025、QB/T 1871、YBB 00252005、YBB 00162002.

Technical index

Model Item | LSSD-01 Leakage and seal strength tester |

Test range | 0 ~ 600 KPa; 0 ~ 87.0 psi(Standard configuration) |

0 ~ 1.6 MPa; 0 ~ 232.1 psi(Purchasing additional) | |

Inflatable head | Φ10 mm (Standard configuration) |

Φ4 mm、Φ1.6 mm (Purchasing additional) | |

Air source pressure | 0.4 MPa ~ 0.9 MPa(Gas source provided by users) |

Air source interface | Φ8 mm Polyurethane pipe |

Size | 300 mm (L) × 310 mm (W) × 180 mm (H) |

Test stand size | 305 mm (L) × 356 mm (W) × 325 mm (H) |

Power supply | AC 220V 50Hz |

Net weight | 23 kg |

Product configuration

Standard configuration | Host, test stand, micro printer |

Purchasing additional | Professional software, communication cable, test accessories (restraint plate test device; open package test device; plastic anti-theft bottle cap sealing performance test device; hose sealing performance test device; aerosol valve sealing performance test device) |

Note | The air source interface of the machine is a Ф 8mm polyurethane pipe; the air source is provided by the user. |