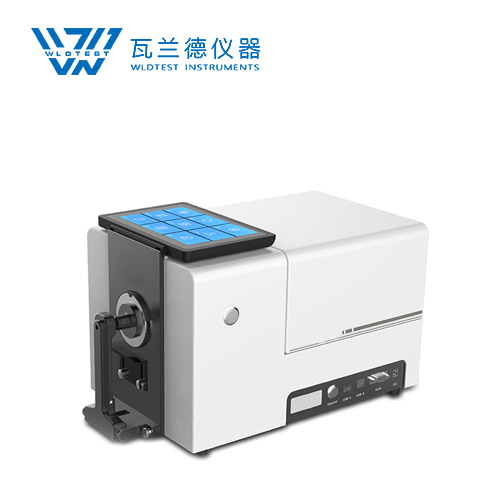

Plastic bottle internal pressure resistance tester

* Positive pressure design principle, simple operation, stable and reliable performance

* Optional test range, wide test range and wide application fields

* Double test method of expansion inhibition and expansion non inhibition

* Rupture test, creep test, creep to rupture test, multiple test modes

- WLD

- Jinan

- anytime

- 50 set/week

- Information

LSSD-02 Plastic bottle internal pressure resistance tester

LSSD-02 is applicable to the quantitative measurement of the sealing strength, heat sealing quality, bag bursting pressure and sealing leakage performance of various soft packaging parts and sterile packaging parts formed by various heat sealing and bonding processes, the quantitative measurement of the sealing performance of various plastic anti-theft bottle caps, and the quantitative measurement of the overall sealing performance, pressure resistance strength, cap body connection strength, peeling strength, heat sealing edge sealing strength, street piercing strength and other indicators of various soft pipes.

Feature

GB、ASTM、ISO Multi Standard compatibility

Positive pressure design principle, simple operation, stable and reliable performance

Optional test range, wide test range and wide application fields

Double test method of expansion inhibition and expansion non inhibition

Rupture test, creep test, creep to rupture test, multiple test modes

The test process is "one key" operation, intelligent and high test efficiency

High definition large screen LCD display of test data, automatic statistics and printing of results

Test attachment support, flexible test mode, compatibility and diversification

Standard USB interface configuration, computer software support, multiple unit display of results

It can realize the information sharing of test data between LAN and Internet

Test principle

After a certain pressure of gas is filled into the sample by setting parameters, the overall sealing performance of the sample is judged by detecting the change of air pressure inside the sample through the pressure sensor, and the pressure resistance and bursting performance of the sample are tested with the specified air pressure.

Reference standard

GB 10440、GB 18454、GB 19741、GB 17447、ASTM F1140、ASTM F2054、ISO 11607-1、ISO 11607-2、GB/T 17876、GB/T 10004、GB/T 10005、 BB/T 0003、BB/T 0025、QB/T 1871、YBB 00252005、YBB 00162002

Parameter

Test range | 0 ~ 600 KPa; 0 ~ 87.0 psi(standard) |

0 ~ 1.6 MPa; 0 ~ 232.1 psi(optional) | |

Inflatable head | Φ10 mm (standard) |

Φ4 mm、Φ1.6 mm (optional) | |

Air supply pressure | 0.4 MPa ~ 0.9 MPa(Air source provided by the user) |

Accuracy | ±1% |

air connection | Φ6mm Polyurethane pipe |

Overall dimension | 300 mm (L) × 310 mm (W) × 180 mm (H) |

Size of test seat | 305 mm (L) × 356 mm (W) × 325 mm (H) |

Power | AC 220V 50Hz |