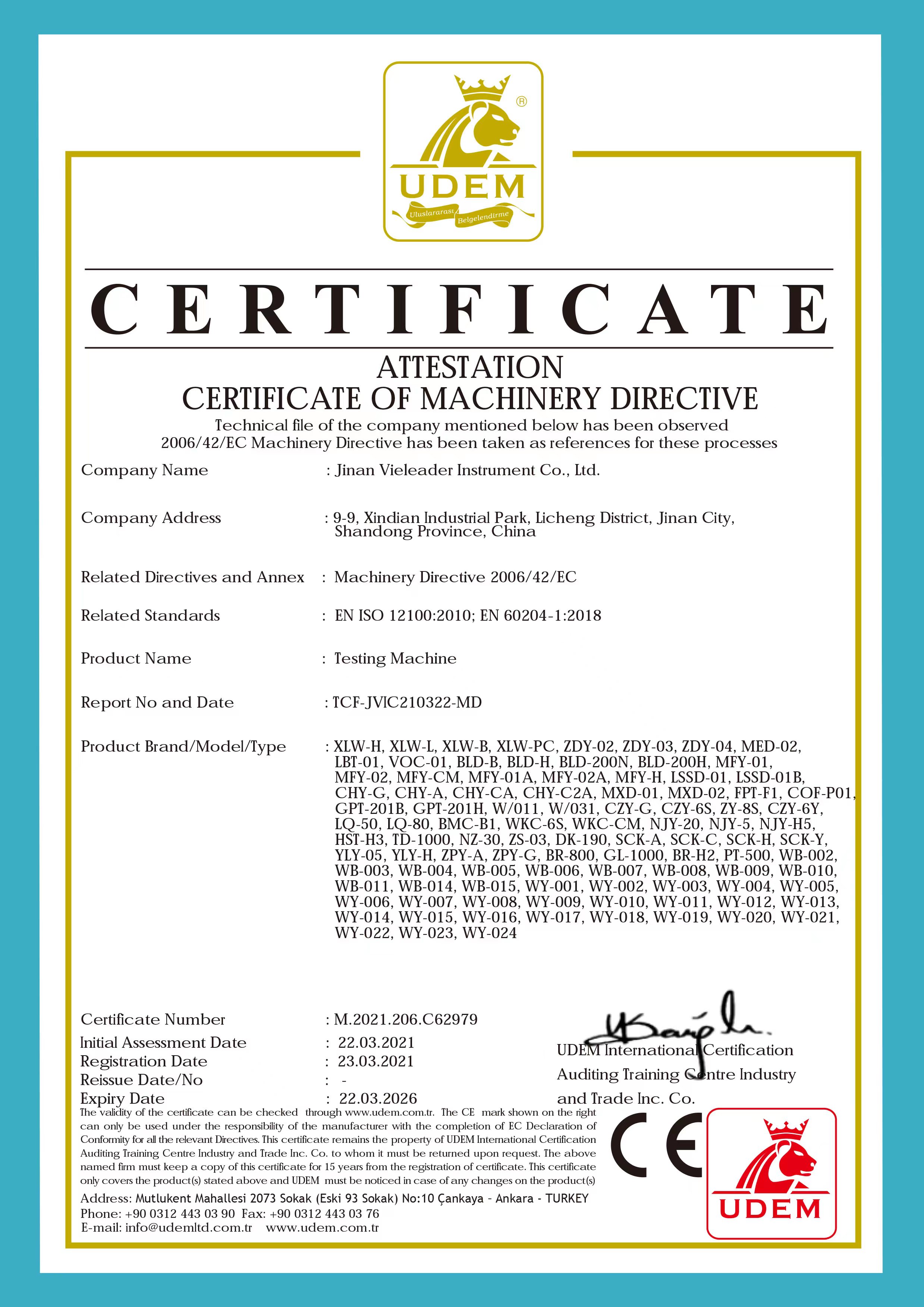

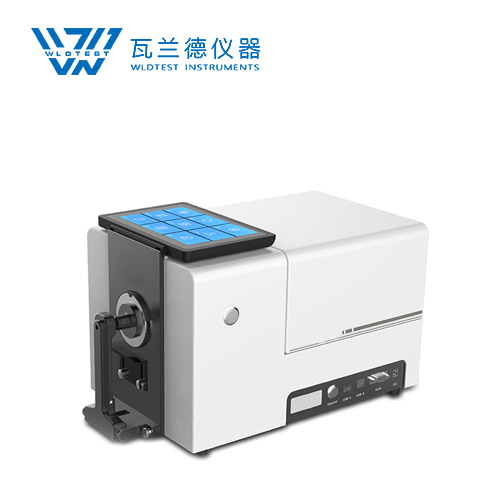

Non-destructive airtightness tester Vacuum decay method

*Detectable below 1μm

*Fast test time and high accuracy

*Numerical values are reproducible

*Non-destructive testing

*Multi-level user rights

*Free calibration, no external sensors required

- WLD

- Jinan

- anytime

- 50 set/week

- Information

Non-destructive airtightness tester

The non-destructive seal tester is developed according to the standard "ASTM F2338-2013 Standard Test Method for Package Leakage - Vacuum Decay Method".

It is professionally used for non-destructive positive and negative pressure leak testing of various empty/pre-filled syringes, water and powder bottles (glass/plastic), filled and capped bottles, milk powder cans, other rigid packaging containers, electrical components

The micro-leakage test for non-destructive positive and negative pressure of specimens, etc. This product adopts advanced design and rigorous, scientific calculation method to ensure its rapid testing and high accuracy and

high stability. It can also meet the user's non-standard (software or test fixture) customization.

Feature

v Detectable below 1μm

v Fast test time and high accuracy

v Numerical values are reproducible

v Non-destructive testing

v Multi-level user rights

v Free calibration, no external sensors required

Principle

The base vessel and the container under test are ensured to be sealed without leakage, and after putting the specimen into the container under test, the pressure change of the container under test is caused by the gas leakage of the specimen. The pressure change is detected by the differential pressure sensor, and then the leakage aperture and the leakage flow rate can be deduced through the formula.

Application

It is professionally used for non-destructive positive and negative pressure leak testing of various empty/pre-filled syringes, water and powder bottles (glass/plastic), filled and capped bottles, milk powder cans, other rigid packaging containers, electrical components

Parameter

Test system | Dual sensors(Optional multi-sensor) |

Positive pressure range | 0~300kpa/0~43.5psi /0~3000mbar |

Vacuum range | 0~-100kpa/0~-14.5psi /0~-1000mbar |

Precision | 0.01CCM |

Test Unit | mbar/pa/psi |

Test Time | 5-30s |

Pressure Resolution | 1pa/0.01mbar/0.0001psi |

Data Transfer | USB |

Data Storage | Excel |

Management rights | Three levels of management authority |

Size | 320×510×320mm |

Power | 220V50Hz |